Critical Equipment Manufacture and Welding Sequence

Critical equipment fabrication requires a strong focus on welding techniques. It is important to ensure that proper welding techniques are employed to achieve high-quality and

Century has a proven track record spanning 75 years, delivering intricate and technically advanced engineering solutions to diverse industries such as mining, defence, power, water, and rail.

Century collaborates closely with clients, employing specialised account managers and support teams, enabling an in-depth understanding of each client’s unique needs, and ensuring the development of products designed for lasting durability.

With ISO accreditation across all industry-required areas, Century is dedicated to conforming to customer quality requirements and standards and is recognised as a trusted manufacturer of critical components and equipment.

Learn more below about Century’s 8 Core Capabilities

Special purpose design from concept and problem-solving to reverse engineering and refurbishment.

Core capabilities

Deliverables / output

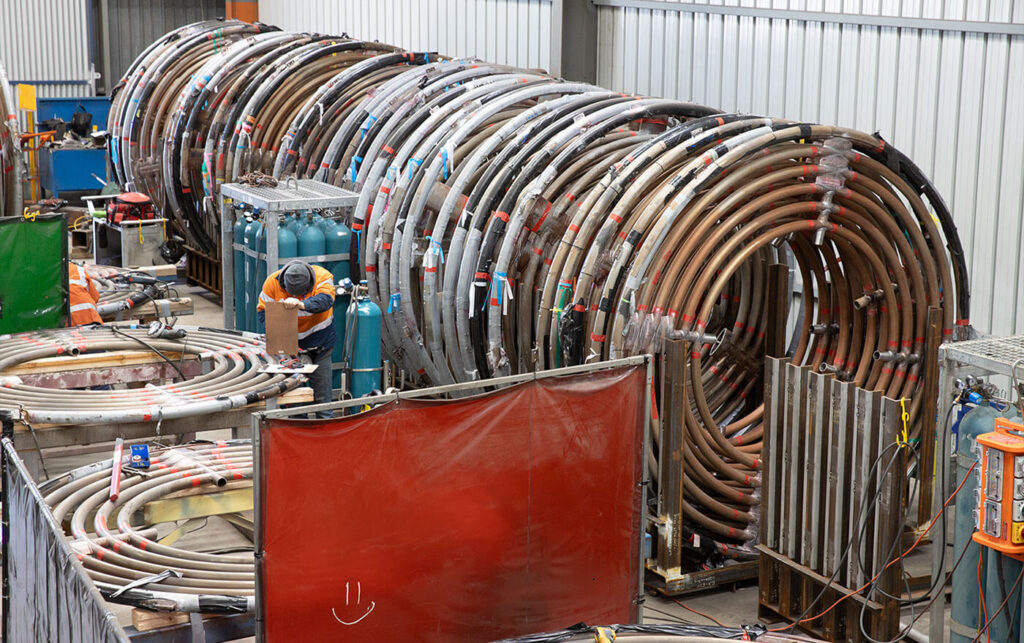

Specialist in intricate and custom-designed structures, cutting-edge techniques to defence standards. Mechanical Pipe Spooling and Pressure Vessel Manufacture.

Core capabilities

Deliverables / output

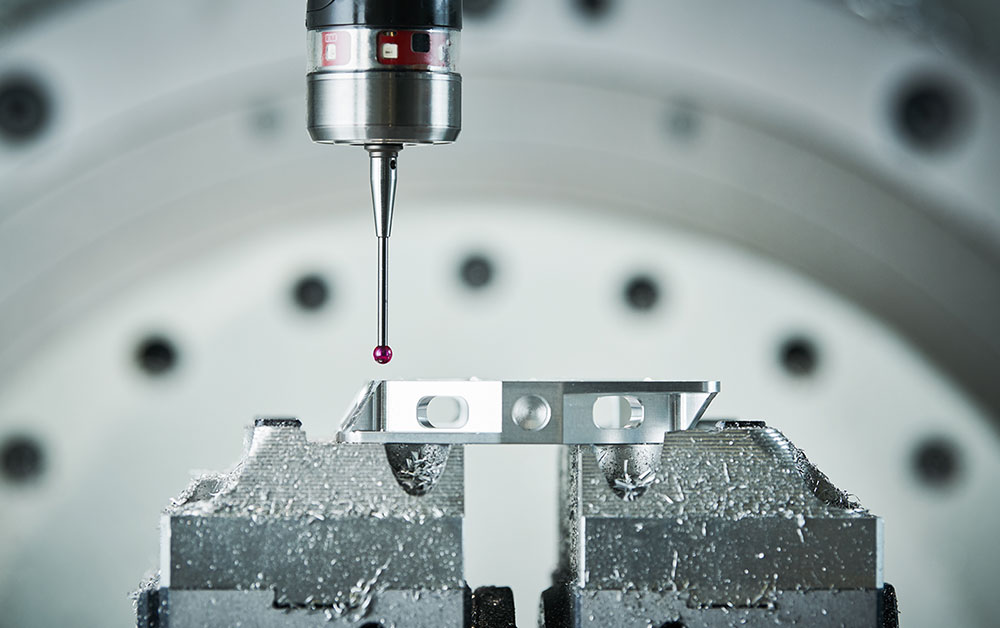

Advanced machining technologies, precise and high-quality machining solutions, and surface treatments to meet demanding specifications.

Core capabilities

Deliverables / output

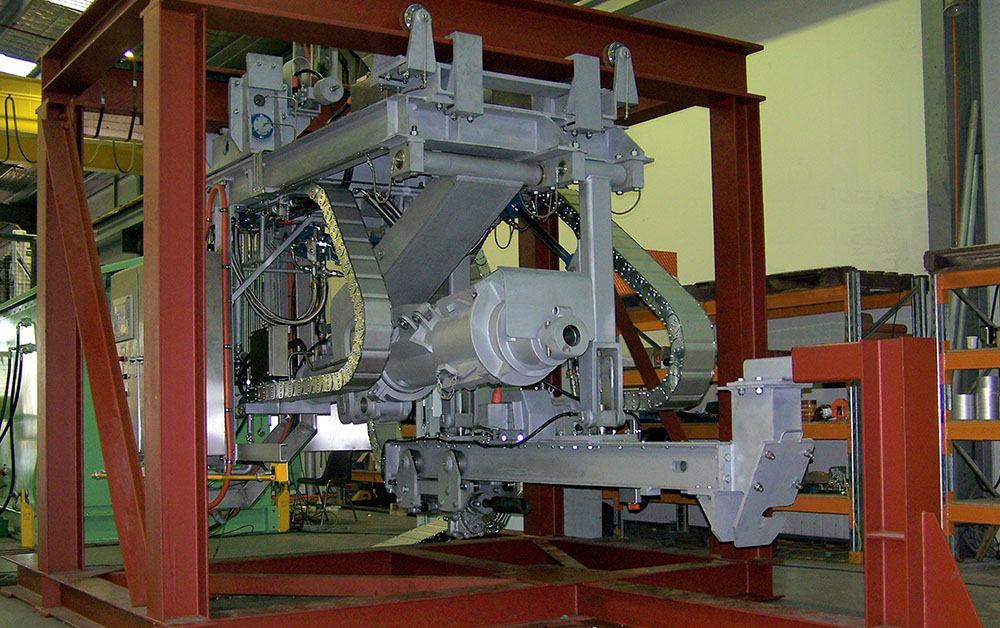

Specifically designed for Heavy Engineering, Large Component and multi processes production with comprehensive surface treatment and painting.

Core capabilities

Deliverables / output

Complete through process quality control, inspection, traceability, and reporting. Rigorous testing and validation to deliver functionality, compliance within industry standards and client specifications.

Core Capabilities

Deliverables / output

Experienced in meticulous assembly of intricate and multifaceted products, and efficient integration of various components.

Core capabilities

Deliverables / output

Comprehensive through life support and maintenance, ensuring optimal performance and longevity of product lifecycle.

Core capabilities

Deliverables / output

Project management and engineering expertise from cross industry experience work force.

Core capabilities

Deliverables / output

Critical equipment fabrication requires a strong focus on welding techniques. It is important to ensure that proper welding techniques are employed to achieve high-quality and

Effectively implementing quality management systems in manufacturing ecosystems for both mining and defence requires detailed knowledge of both industries. There are key parallels and distinctions

In critical equipment fabrication, post-welding inspections and quality assurance play a crucial role in ensuring the overall integrity and reliability of the fabricated structures. Welding

Implementing quality management systems in defence manufacturing presents challenges that require careful consideration and strategic planning. Century Engineering addresses these challenges and provides the broader